言語の変更 :

Components for hygiene-sensitive areas in the food industry

Use of igus® products in the food industry

Selected motion plastic for the food industry

1

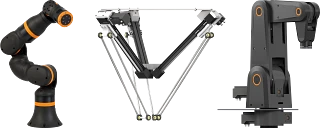

協働ロボット、デルタピッカー、ゲルアームロボットなど ...

包装機械における自動化

シンプルなプロセスの自動化、既存システムへの迅速な統合、そして迅速な投資回収。それが、「ローコストオートメーション」において、イグスが掲げる目標です。

包装機械における位置調整 ― 手動調整からスマート位置決めへ

Successful in use

Aggressive environmental conditions (cleaning, extreme temperatures, dust and dirt), high hygiene standards, long service life in continuous operation, fast and flexible format adjustments... The requirements in the packaging, food and beverage industries are diverse. Here you can find out more about the successful use of our motion plastic by our customers.

1

ホワイトペーパー―コールスタライジング処理とトライボポリマー

高純度で、高いコストパフォーマンス、正確かつ高速な処理が求められる業界では、コールスタライジング処理と高機能ポリマーの組み合わせが標準になるはずです。

Tested for real use in the test laboratory

iglidur® bearings and drylin® linear technology are put through their paces in the industry's largest plastic test laboratory. Among other things, they are tested for media resistance (e.g. cleaning media), continuous load and low-noise operation. The results are fed into our tools for calculating service life and enable precise predictions to be made about durability.

Upon request, igus® also carries out customer tests in order to test the use of the products under very individual conditions.

お問合せ

ご不明な点がございましたら、お気軽にお問い合わせください。

イグス株式会社03-5819-2030メールで問い合わせる

お問合せ対応時間

電話およびチャットでの対応時間:

月曜~金曜:8:45~18:00