組立て済みエナジーチェーン: レディーチェーンの使用事例

すぐに設置できるオートメーション向けエネルギー供給システム

機械や産業プラントの自動化には、組立て済みのエネルギー供給システムを採用するさまざまな理由があります。組立て済みエナジーチェーンのレディーチェーンは、木材加工機械、繊維機械、計測システム技術、特殊機械製造など、多くの産業分野で使用されています。オートメーション向けの組立済みエネルギー供給システムによって、製造コストが削減され、故障の原因が実質的に排除されます。プロジェクトの計画作業は少なくて済む一方、信頼性は向上します。組立機械やハンドリング装置、コンベヤ、機械設計など、様々な機械や設備でお使いいただけます。採用事例の一例

Woodworking industry

Module Connect ensures fast connection of the energy supply in the wood industryWoodworking industry

Milking technology

Pre-assembled energy chains enable comfortable milkingMilking technology

多軸旋盤内のエナジーチェーン

ベクター金賞はイタリアのGildemeister Italiana社の多軸旋盤に贈られました。多軸旋盤内のエナジーチェーン

包装機械

モジュールコネクトが包装機械の迅速メンテナンスを実現包装機械

Bridge construction

Pre-assembled e-chain system ensures a fail-safe energy supply at the Memorial Bridge in New HampshireBridge construction

Measuring system for extruder

Pre-assembled energy supply systems for measuring and control systems in blown film extrusion.Measuring system for extruder

Heat and dust: energy supply system for indoor crane under adverse conditions

At Thyssen Krupp's Duisburg hot rolling mill, a slab transport crane has been fitted with pre-assembled roller energy chains for the energy supply system. They work reliably under adverse environmental conditions such as heat and dust.Heat and dust: energy supply system for indoor crane under adverse conditions

Machining centre

Assembly-friendly and compactly designed complete solution from igus reliably supplies machining centres with energy.Machining centre

Loading and unloading facility

Rigorous requirements imposed on the energy supply: Cycle times and narrow bend radii are a considerable strain on energy supply and lines.Loading and unloading facility

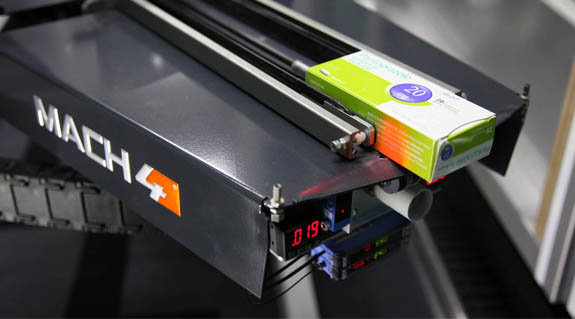

Energy chains in a picking system with 20,000 movements a day

Durable, quiet, low-abrasion, space-saving: these were the high requirements of this warehouse for medicines of Omnicell GmbH for the cable guidance.Energy chains in a picking system with 20,000 movements a day

Shore power connections

At the Mongstad offshore base, flexible harnessed energy supply systems enable 3,000 shore-power connections per year.Shore power connections

Energy chains in ROMI machining centres

The pre-assembled energy chain reliably supplies machining centres with energy at high travel speeds and in limited installation spaces.Energy chains in ROMI machining centres

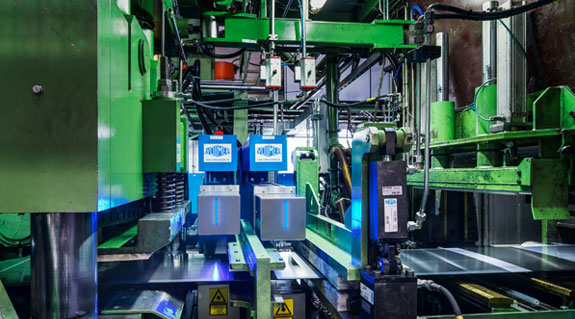

Robotic machining centres

Ready-to-install readychain® systems from igus® reduce assembly times and minimise process costs and errors.Robotic machining centres

Automation solution

Harnessed energy supply systems ensure reliable automatic loading of machining centres.Automation solution

Pre-assembled energy chain ensures data transmission in crane construction

In crane construction, the demands on operational safety are particularly high due to the long travels. Expensive stoppages and thus downtimes must be avoided at all costs.Pre-assembled energy chain ensures data transmission in crane construction

Lifting platforms

readychain® harnessed energy chains from igus enable safe and precise working at a great height as well as faster maintenance.Lifting platforms

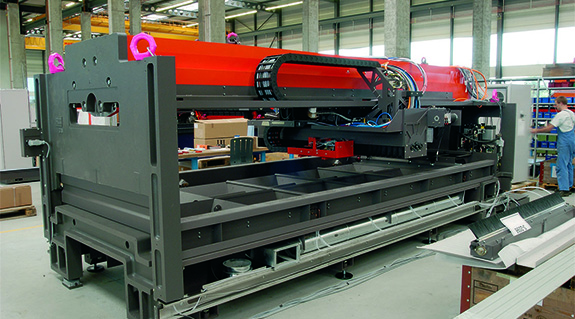

Robust cable guidance for dynamic Bystronic laser cutting machines

Because of the extremely high demands on dynamics and the high lateral accelerations, the energy chain has to be stable, robust, and not too heavy.Robust cable guidance for dynamic Bystronic laser cutting machines

Laser measuring instruments

readychain systems ensure precision in laser measuring devices for rolling mills.Laser measuring instruments

50% more storage space thanks to pre-assembled energy supply systems in an indoor crane

This fully automatic crane system from Kranserive Herz works with pre-assembled plastic energy chains with extremely low clearance height.50% more storage space thanks to pre-assembled energy supply systems in an indoor crane

Energy chains replace trailing cables on bridge crane in concrete plant

With a completely pre-assembled system from igus®, the installation times could be kept short and a longer production downtime avoided.Energy chains replace trailing cables on bridge crane in concrete plant

Quickly installed energy chain in a Waldrich Coburg gantry milling machine

Pre-assembled energy supply systems for machine tool construction saved several weeks of assembly time in this application.Quickly installed energy chain in a Waldrich Coburg gantry milling machine

_1170.jpg)