言語の変更 :

1

どのエクステンダークロスバー付きE-チェーンを選べばいいのか?

2002年にウェストファル社で行われたアプリケーション事例が、エクステンダークロスバー付きエナジーチェーン開発の出発点となりました。CNC加工機でホースをガイドする場合、どのチェーンが適しているかは、メーカーTrimaのアプリケーションケースでご覧いただけます:

今すぐ調べる

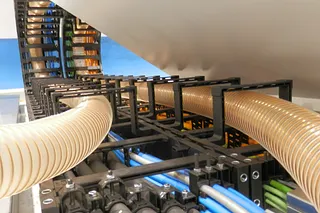

サクションホースをピギーバックしたエナジーチェーン

標準部品から生まれた新しいタイプのエネルギー供給システム

特殊構造か標準ソリューションか?顧客は、時間のかかるスペアパーツの調達や高い開発費といった特別な設計上の問題を抱えることなく、技術的に最適化された機械を求めている。ドイツ・ハーメルンを拠点とするWestphal Maschinenbau社がイグスコンポーネントで実証しているように、当初は二律背反のように見えることでも実現可能です。標準部品から新しいタイプのエネルギー供給システムが生まれ、そのピギーバック原理によって、木材やサンドイッチ加工における大容量のサクションホースに、最終的に明確な居場所が与えられ、改良の余地が生まれた。

"問題の回避はもう終わりを告げた"

木材、アルミ形材、サンドイッチの加工では、切粉を排出するための大型の吸引装置が特徴的です。しかし、機械がますます最新式になり、より高い性能を発揮し続けるためには、天井から吊り下げられた吸引ホースは実現不可能でした。早急に解決策が必要でした。"" 、ウェストファルはこの問題についてこう語る。"そこで、私たちは解決策を探し求めました。" そして、ヴェストファーレンらしいオープンさでそれを実行したのです」。ヴェストファーレン社は、エネルギー供給システムのサプライヤーに、自社の顧客と同じように有能で透明な存在であってほしいと願っていました。"イグスのセールス・エンジニアにはすぐに感心しました。彼はすぐに来てくれて、数時間以内に適格な見積書を提出してくれました。また、設置中に疑問が生じると、すぐに駆けつけてサポートしてくれました。私たちは今、問題を回避することに終止符を打ち、私たちが望むように機械を改良することを可能にするソリューションを手に入れました。"

では、具体的にどのような解決策があったのだろうか?

Westphal Maschinenbauとイグスのコラボレーションにより、1600.40.250.0型エネルギー供給システムによるピギーバックソリューションが誕生しました。全体がプラスチック製で、金属製のねじ接続は一切不要です。そのため、ケーブルやホースに特に優しくなっています。また

- エネルギー供給システムの片側にある大きくて比較的壊れやすいホースと、反対側にある空気圧およびエネルギーケーブルを確実に分離します。

- この場合、250mmという大口径のホースを最小限の材料と重量でガイドします。

- は、イグスのモジュール式エネルギー供給システムに基づいており、スペアパーツの供給が保証されています。

"" 、イグスのミヒャエル・ブラスは言います。43,000を超える部品があるため、モジュラーシステムから特別なソリューションを導入することも可能です。ここでは、顧客が再注文の際に待ち時間が発生しないよう、標準部品を再配置しました。""

将来のためのオプション

イグスのエネルギー供給システムは、ウェストファルの機械に組み込まれた柔軟性と拡張性において、大きな役割を果たしています。"これらのシステムにより、複数の軸とリニアロボットで最適なホースとケーブルガイダンスを実現できるのです」" とウェストファル社は言う。"顧客は、できればすべての接続ケーブル(データ、エネルギー、圧縮空気、抽出)を中央から供給できるプラグイン式マシンを求めています。"性能の向上もトレンドのひとつだ:ウェストファールはすでに、3台の独立したリニアロボットと12軸の機械を使用している。それだけではありません。最大16軸、最大40メートルの移動がすでに計画されている。多数の供給ラインにより、このような大規模で複雑なシステムは、強力なエネルギー供給システムなしでは考えられない。これにより、Westphal Maschinenbau GmbHとigus GmbHがうまく協力できる新たな分野が切り開かれた。

使用製品はこちら

お問合せ

ご不明な点がございましたら、お気軽にお問い合わせください。

イグス株式会社03-5819-2500メールで問い合わせる

お問合せ対応時間

電話およびチャットでの対応時間:

月曜~金曜:8:45~18:00